What is the car differential?

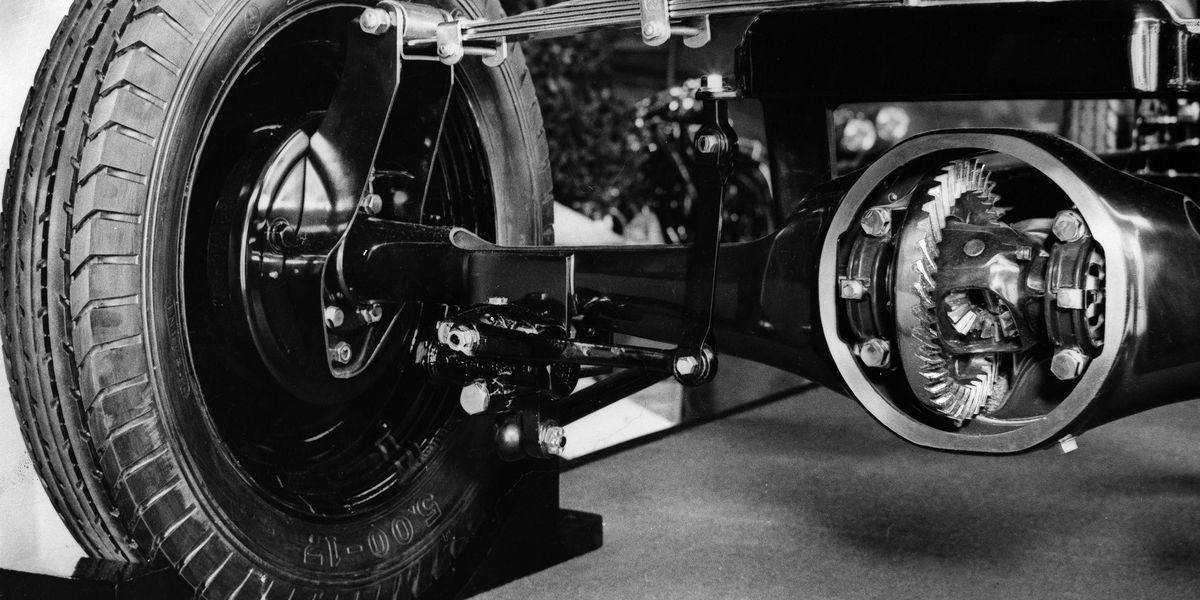

The differential is a speed system that allows different drive wheels (wheels that are supplied with engine power) on the same axle to rotate at different speeds, such as when the car is spinning.

A differential is also the component by which a rotating drive shaft can change direction; for example, in a rear-wheel drive car whose drive shaft extends the length of the car, it joins and transfers power to an axle that runs perpendicular to the car to drive the left and right wheels.

Differentials are sealed, low maintenance components that are expected to last the life of the vehicle but may have a recommended service life to check and / or replace the oil. Keep in mind that an all-wheel drive car can have two or more differentials. A faulty differential can cause vibration, cornering and / or noise from noise to screaming.

How does the differential work?

The differential takes the rotational movement from the axle in the gearbox and distributes it to the wheels through the planetary shafts. This distribution is differentiated so that the wheels run at the required optimum speed.

If a vehicle changes direction, the distance traveled by the wheels also changes. The wheels on the inside will travel a shorter distance than the outside. In this case, the differential helps keep the wheels balanced at all times.

However, there are cases where locking the differential is beneficial because it helps the vehicle to cross sections of road where high grip is needed.

However, there are cases where locking the differential is beneficial because it helps the vehicle to cross sections of road where high grip is needed.

For such cases, the lockable differential has been invented which practically ensures that all the wheels of a vehicle rotate at the same rotational speed.

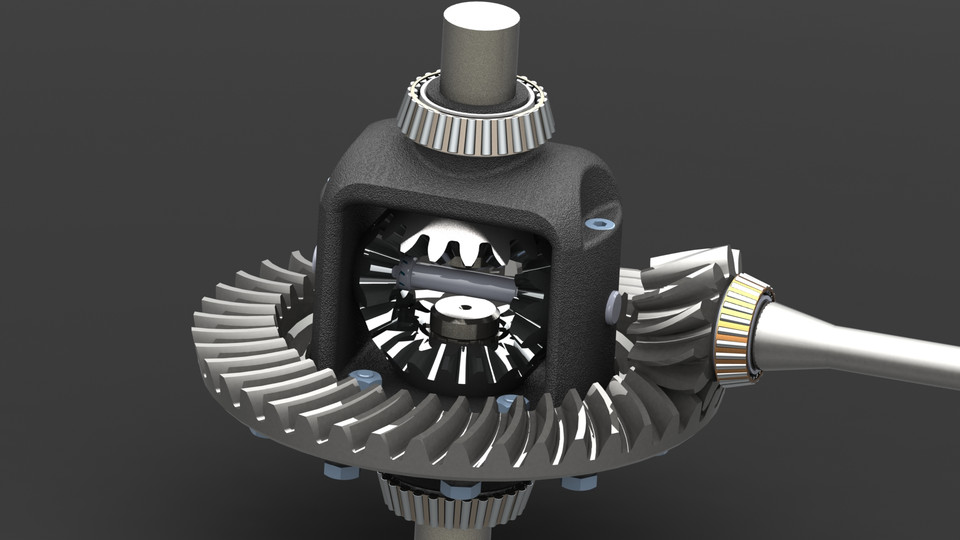

In a straight line, the housing, being integral with the crown driven by the output shaft of the gearbox, rotates together with the whole assembly and drives the planetary sprockets, further the movement reaching through the shafts to the drive wheels. In this situation, the satellite sprockets do not rotate around their own axis.

When one of the wheels skates, while the housing is moving, the satellite sprockets will also rotate inside around their own axle, while the other wheel of the vehicle will remain stationary.

Hence the main drawback of the differential: if one of the wheels loses grip, it will spin in a vacuum, the engine torque will not be transferred to the other wheel and the vehicle will not be able to move forward. To eliminate this shortcoming, devices are used that distribute the torque to both wheels.

What is a car differential made of?

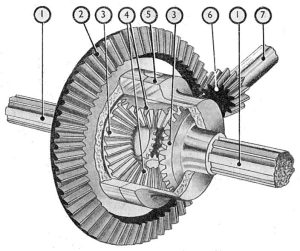

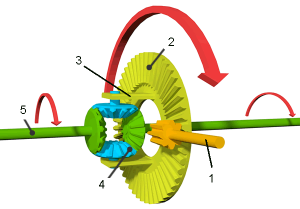

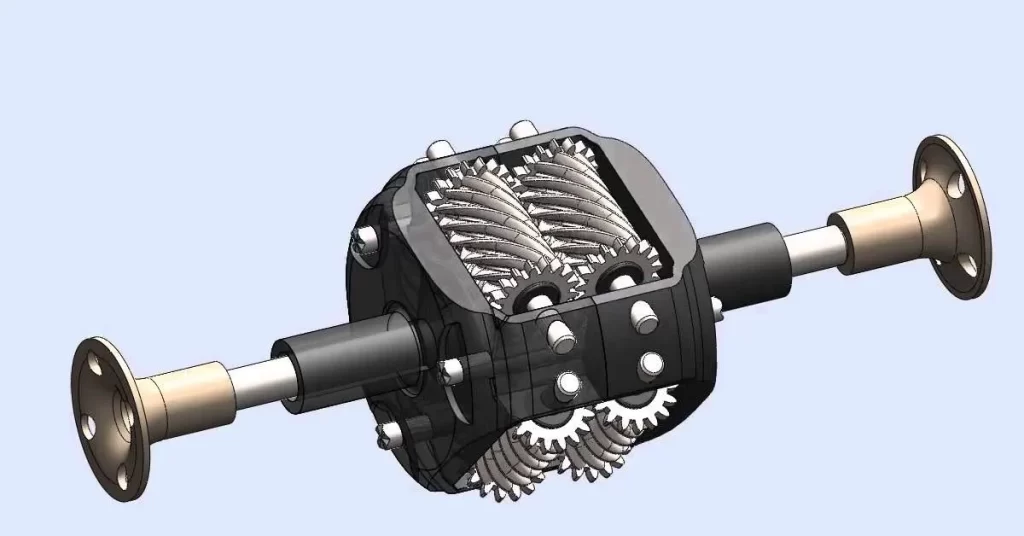

The kinetic energy comes from the cardan motor as a speed movement. The differential consists of 6 gears of different sizes and different inclinations.

A gimbal gear called a pinion (6) spins a larger wheel, called a base ring (2), which is connected in turn by two independent wheels called the spider wheel (4). And these are connected to the two traction wheels (3), one for each planetary.

Everything is based on easy operation on bearings, in a housing filled with special oil.

The roles of a car differential

In addition to avoiding the wheels turning at the same speed, the differential has two other roles:

- One is the transformation of the longitudinal movement from the gimbal into transverse movement to the wheels.

- The second role is to reduce the cardan speed before the rotational energy reaches the wheels, thus increasing the torque.

Types of differentials

Open Differential

It is the most common type of differential in the case of production cars, being also the simplest (and the cheapest for the manufacturer). It consists of gears, a main pinion, two secondary and two more that are directly connected by the planetary.

The main pinion (like a flywheel) is the one that receives the torque from the engine and then transmits it to the planetary via the other pairs of smaller sprockets.

In a straight line, as both wheels (tires) rotate at the same speed, the center sprocket transmits engine power directly to the sprockets coupled to the planetary gears, without driving the other pair of intermediate sprockets.

But when the car makes a turn, the wheels will have to turn at different speeds, and the two intermediate sprockets will intervene and “engage” the other, causing a decrease in speed of the wheel inside the turn and a proportional increase wheel speed on the outside.

This solves any problems due to tire wear, overloading of the transmission elements, as well as grip problems.

The open differential still has some peculiarities. The fact that it tries to apply the same torque to both wheels, moreover, the maximum torque that can be transmitted to one wheel is directly related to the maximum torque that the other wheel can transfer to the tread. In other words, this differential cannot transmit more torque to the wheels than the maximum that will not cause the wheels to skid.

The open differential cannot secure the wheel with more grip than the maximum torque that the wheel with less grip can transfer to the tread.

It can be said that the open differential will try to transfer the maximum torque to the wheel that benefits from the least grip, causing all this torque to be lost by rotating the respective wheel idle.

For example, if one wheel is on the ice and the other on the asphalt, the differential will only ensure that the wheel on the asphalt has the maximum torque that will not cause the other wheel on the ice to skate. And it doesn’t take much torque for a wheel on ice to skate.

Therefore, in such a situation, the wheel on the asphalt, which could push the car forward, will not be able to do this because it reaches exactly the same torque that reaches the one on the ice.

Especially in off-road situations, this situation is the most difficult. It can happen that one of the drive wheels is suspended, so it benefits from 0 (zero) grip. In this case, the open differential will not be able to handle the situation – it will not transfer any torque to the other wheel and the car will remain stuck.

An open differential will not be able to transmit to the wheel with better grip than the torque of the wheel with the lowest grip. In this case, even if we are talking about asphalt, the adhesion will be influenced by the mass transfer, up to the level where the wheel that should ensure the acceleration and, implicitly, the recovery from skidding, from overtaking, could not do this, not benefiting from the couple.

It should not be understood that the open differential is, by definition, a rudimentary system. On the contrary, it is a very good system, in situations of good grip and, especially, in the case of a reasonable behavior of the driver .

The latest generations of cars benefit from a system designed to “control the limitations” of the open differential, through the intervention of electronics and ABS for the management of such emergencies. The generic term is ETC (Electronic Traction Control).

Differential locked (self-locking) or “closed”

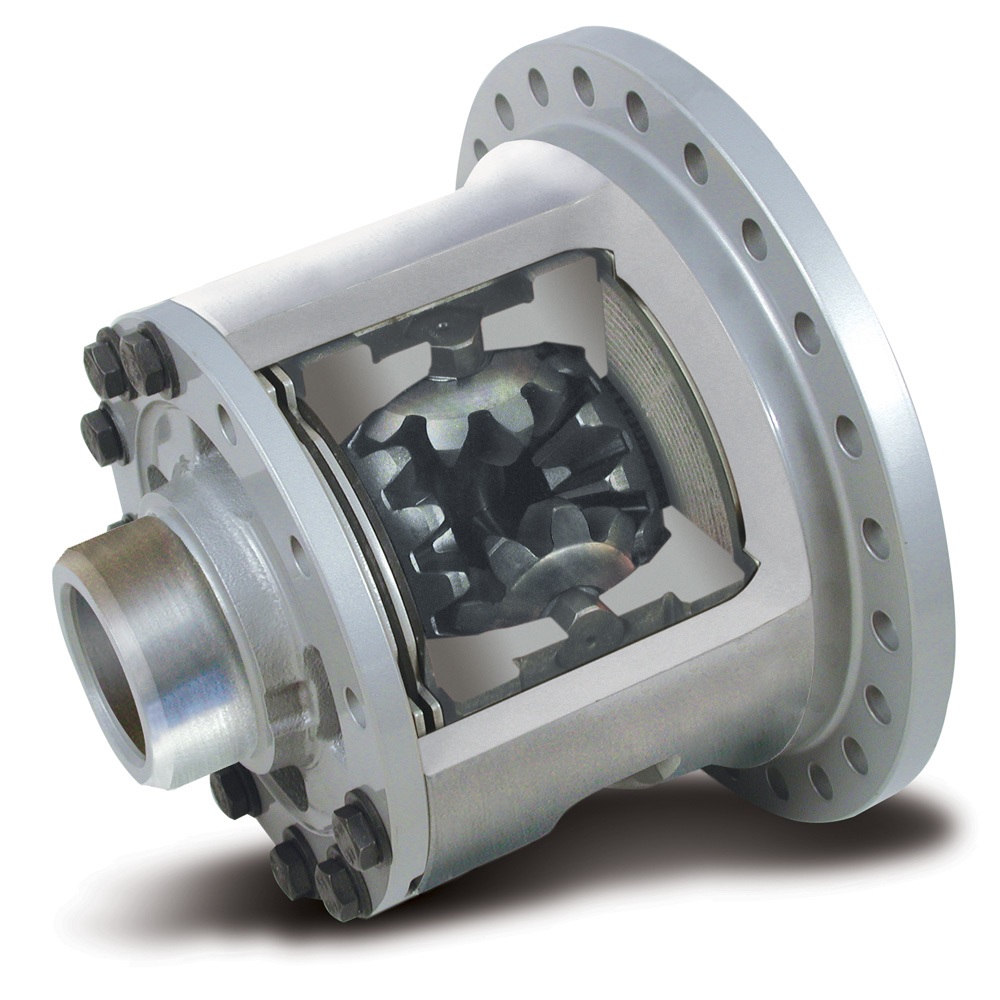

If at the open differential the two pinions connected by the planetary gear were welded together, regardless of the rotation of the steering wheel or the available grip, the two wheels would be forced to move simultaneously, with the same speed of rotation. It is the simplest explanation of the locked differential.

Self-locking systems have different systems (mechanical, pneumatic, hydraulic, etc.) designed to lock the internal sprockets, but this is the basic principle.

The most important application (the biggest advantage) occurs when one of the wheels has no grip at all. In this case, a self-locking device will intervene and transmit all the torque provided by the engine to the wheel with good grip, even if the other wheel is suspended. It does not mean that he will do this “smart”.

That is, its mode of operation does not involve any sensor system and a computer to tell it to which wheel the torque should be transmitted. A self-locking device will do this “blindly”, simply mechanically. Hence the almost exclusive area of use of the self-locking, respectively off-road.

In most cases, the tire on the outside of the corner will run smoothly on the ground, while the tire on the inside (which has less grip due to mass transfer) will be forced due to the differential to rotate at the same speed (as the one on the outside), will enter a skating phase, which will lead to premature wear.

In addition, the car will always have a tendency to return to the straight line position, which will make every turn much more difficult, affecting stability and comfort.

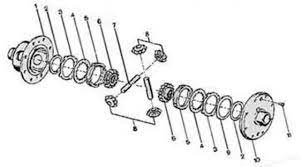

Self-locking differential with slats

It is without a doubt the most widespread in the field of motorsport, due to its efficiency as well as its small size, which recommends it for replacing the series differential without further modifications. The torque is not transmitted directly from the housing to the satellite shaft as a single differential, but through two pressure rings solid in rotation with the differential housing.

As the applied moment increases, the axes of the 4 satellites move on the inclined planes of the rings away from them, and they press on the disk packets.

The size and number of friction discs determine the torque that can be transferred, and the angle at which the inclined planes are machined determines the moment of coupling of the differential, a smoother slope causing locking at smaller differences between the rotational speeds of the planetary sprockets.

Limited Slip Differential – LSD (Limited Slip Differential)

There are several types of LSD: viscous coupling, clutch pads (with or without torque transfer springs) and its subdivisions: passive (mechanical), hydraulic and electronic, and other forms and types derived therefrom.

A simple definition of LSD is as follows: the limited slip differential is a compromise between the “open differential” and the locking differential, capable of behaving similarly to the blocking differential in situations of significant imbalance of adhesion, and similar to the open differential, in the basic application of differentials, that which allows the wheels to rotate at different speeds when cornering.

Although they are different constructively and as a mode of operation, all the types of LSD listed above have the mission to ensure the same thing, described in the definition.

Torsen type differentials (Quaife, Peloquin etc.)

Torsen is a term derived from the expression “torque sensitive”, which describes the very operation of the system.

Torsen is the type of differential whose main feature – in which it also resides its quality and performance – is that it reacts immediately to any torque imbalance between the two drive wheels, directing the torque to the wheel that can successfully transfer it to the surface. rolling, ie towards the wheel with high grip.

The fundamental difference between LSD and the open differential is that the open differential will always send the engine torque to the wheel with less grip, and the transmitted torque will be lost by the spinning of the wheel.

These types of LSDs (Torsen’s Quattro and Quaife are similar but not identical) have what is called a “multiplication ratio” of the torque, generally with values of 1: 4 or 1: 5. a torque of 30 Nm is directed to the wheel with minimum grip, the LSD will instantly direct a torque of approximately 120 Nm or 150 Nm to the wheel with better grip, ie 4 or 5 times higher than the minimum torque on the wheel with low adhesion. However, there are some disadvantages.

For example, an LSD will never be able to act as a locking differential if one of the wheels has 0 (zero) grip, ie it is suspended. And this is due to the multiplication ratio: that is, if a torque multiplication ratio is 1: 4, but one of the wheels has 0 (zero) grip, the other will also have 0, because 0Nm x 4 = 0 Nm. For this reason, LSDs are not often used in extreme off-road.

Other (small) disadvantages would be that the LSD is a bit heavier than an open differential, it cannot be set or modified in terms of the multiplication ratio and the maximum torque it can withstand, which it can handle and which comes of the engine.

For the more “sporty” ones, the limited slip differential is spectacular on roads with cornering sequences, as it allows you to accelerate (FWD cars) much earlier and more intensely. Car enthusiasts claim that, after mounting an LSD on front-wheel drive cars, they had the impression that they were behind the wheel of an all-wheel drive.

Haldex coupling

Also used primarily as an interaxial differential, but for semi-permanent all-wheel drive cars or, more correctly, TOD (Torque On Demand when required), and many SUVs (for example, VW models with front-wheel drive and available in 4 × 4 variants), it is practically a multi-disc clutch in oil bath controlled by an electronic control unit by means of a hydraulic actuator that ensures the coupling of the two shafts, input and output, respectively.

This coupling is the basis of the so-called active differentials, as well as the interaxial differential that is equipped for example Mitsubishi Lancer Evo VII and the following.

An interesting application is the so-called AYC (Active Yaw Control), first introduced on the Mitsubishi Evo IV and available on the latest Eclipse Cross , which, using a similar active differential, delivers more torque on the rear wheel from outside corners to allow them to go faster.

Some vehicles use a similar solution but with an electric actuator. For example, BMW’s all-wheel drive xDrive models manufactured after 2003, engage the multi-disc clutch with an electric actuator that drives a cam disc.

4 × 4 vehicles, all-wheel drive

Vehicles that are really destined for rough terrain usually use a non-permanent all-wheel drive, with the front axle being coupled to the driver’s control via a transfer case. Their transmission imparts the same speed to the front and rear shafts, with  a differential on each drive axle.

a differential on each drive axle.

They can be free, self-locking or lockable to order through systems similar to those that engage gears in gearboxes.

4 × 4 cars and SUVs, however, require three differentials, one for each axle and one interaxial to allow different front and rear wheel speeds when cornering.

These three differentials can be limited, the variants presented above, in different combinations.

At present, many manufacturers aim to reduce costs by replacing the limited slip differentials with functions of electronic traction control systems, transferring torque to the wheels with better grip by braking those who tend to skate.

Differential Care

Regular maintenance of any vehicle is a must for changing oil, belts, hoses and other fluids. The differential fluid is no exception. Differential oil is used to lubricate manual transmissions and differentials. It is similar to the importance of engine oil for the engine. It plays a vital role in protecting the differential and transmission, allowing them to operate safely and smoothly.

The used differential fluid becomes dirty and contaminated over time. Continued driving with contaminated liquid is risky, as it can lead to unnecessary wear of the components, leading to permanent damage. Sign the differential needs service:

- Noise only at deceleration.

- A howl or whistle while accelerating at low or high speeds.

- Flashing or pushing at speeds above 20 MPH, but changing as you turn.

- Regular sound every few steps or when you start moving.

- Constant vibration that increases with vehicle speed.

The differential fluid is also known as gear oil or gearbox oil (changed every 30,000 miles to no more than 60,000 miles) by a qualified technician. Clean and fresh oil allows better protection of the differential, which leads to a safer ride. As with any vehicle component, well-lubricated parts are equal to optimum performance.